Top Quality Roofing Making Machine for Sale - Ultimate Guide

By:Admin

Innovation and advancement in technology are revolutionizing the way we do business and transforming various industries around the world. The roofing industry, in particular, has seen remarkable progress with the introduction of advanced machinery and equipment. One such groundbreaking development is the Roofing Making Machine produced by a leading company in the field of manufacturing and construction.

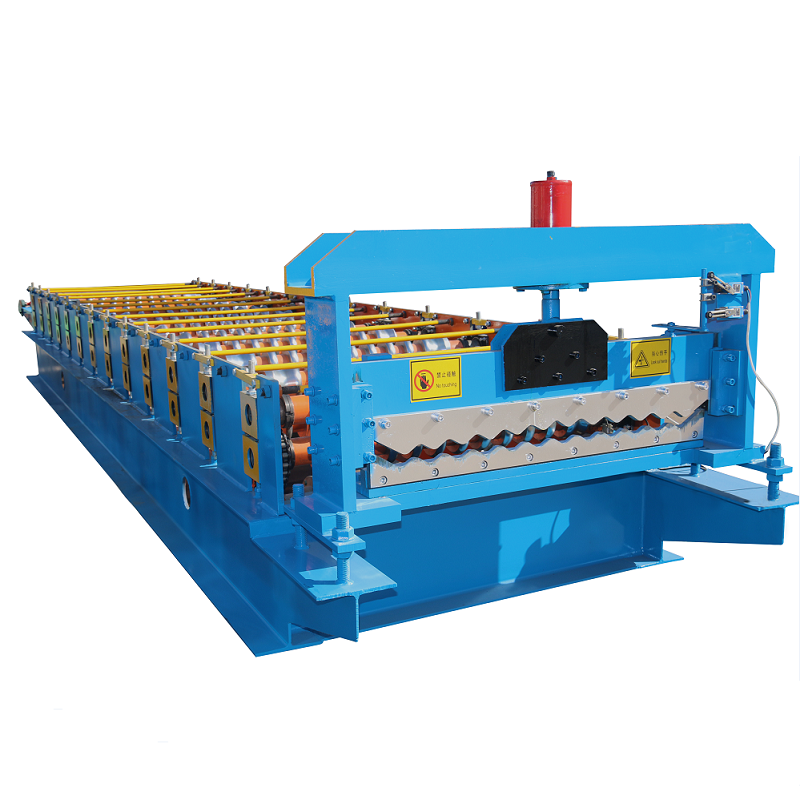

The Roofing Making Machine is a state-of-the-art piece of equipment that has been designed and developed to streamline the process of manufacturing roofing materials. This machine is capable of producing high-quality roofing sheets with precision and efficiency, making it an essential asset for companies involved in the roofing industry.

The company behind the development of this cutting-edge equipment is a renowned name in the manufacturing and construction sector. With a rich history of innovation and a commitment to excellence, the company has established itself as a global leader in providing advanced solutions for the production of building materials. Their expertise in engineering and manufacturing has enabled them to create a Roofing Making Machine that sets new standards in the industry.

The Roofing Making Machine is equipped with advanced technology that allows for seamless and rapid production of roofing materials. It is capable of producing a wide range of roofing sheets, including corrugated, trapezoidal, and other custom designs, meeting the diverse needs of the market. The machine’s precise control and automated operation ensure consistent quality and uniformity in the manufactured roofing sheets, resulting in a superior end product.

The efficiency and productivity of the Roofing Making Machine have been lauded by industry experts and customers alike. Its high-speed production capabilities and low maintenance requirements make it a cost-effective solution for companies looking to enhance their manufacturing processes. By significantly reducing the time and labor required for producing roofing materials, the machine enables businesses to increase their output and meet the growing demand in the market.

Furthermore, the Roofing Making Machine incorporates features that prioritize safety and environmental sustainability. With comprehensive safety mechanisms and energy-efficient operations, the machine upholds the company’s commitment to responsible manufacturing practices. This aligns with the global movement towards environmentally friendly production methods, positioning the company as a responsible and conscientious industry leader.

The company’s dedication to customer satisfaction is evident in its commitment to providing comprehensive support and training for clients who invest in the Roofing Making Machine. From installation and set-up to ongoing maintenance and technical assistance, the company ensures that its customers can maximize the benefits of their investment and optimize the performance of the equipment.

The introduction of the Roofing Making Machine has created a significant impact on the roofing industry, empowering companies to elevate their manufacturing capabilities and deliver superior products to their customers. The machine’s advanced technology and efficiency have set a new benchmark for the industry, driving competitiveness and innovation in the market. Moreover, its adherence to safety and sustainability standards reflects the company’s vision for a progressive and responsible approach to business.

In conclusion, the Roofing Making Machine produced by the pioneering company has emerged as a game-changer in the roofing industry. Its cutting-edge technology, robust performance, and commitment to excellence have redefined the manufacturing process for roofing materials, paving the way for enhanced productivity and quality. As the industry continues to evolve, the Roofing Making Machine stands as a testament to the power of innovation and engineering in creating transformative solutions for businesses. With its proven track record and customer-centric approach, the company and its revolutionary machine are poised to shape the future of the roofing industry.

Company News & Blog

High-Quality Metal Coil Slitting Machine for Efficient Production

Metal Coil Slitting Machine Brings Cutting-Edge Technology to the Manufacturing IndustryIn today's fast-paced manufacturing industry, the demand for precision and efficiency has never been higher. As companies strive to remain competitive in a global market, the need for cutting-edge equipment has become increasingly important. This is where the Metal Coil Slitting Machine, manufactured by a leading company in the industry, comes into play.With a commitment to providing innovative solutions for metal processing, this company has established itself as a trusted provider of high-quality equipment. Their Metal Coil Slitting Machine is a testament to their dedication to meeting the evolving needs of the manufacturing industry. This state-of-the-art machine has revolutionized the process of slitting metal coils, offering a level of precision and efficiency that was previously unheard of.One of the key features of the Metal Coil Slitting Machine is its ability to accurately and consistently slit metal coils to the exact specifications required by the customer. This level of precision is made possible by advanced technology and a design that has been optimized for performance. The machine is capable of processing a wide range of metal materials, including stainless steel, aluminum, copper, and more, making it incredibly versatile and adaptable to a variety of manufacturing needs.In addition to its precision, the Metal Coil Slitting Machine also offers unmatched efficiency. With high-speed processing capabilities and an intuitive control system, the machine is able to maximize productivity and minimize downtime. This is essential for companies looking to streamline their operations and meet tight production deadlines.Furthermore, the Metal Coil Slitting Machine is designed with operator convenience in mind. The user-friendly interface and advanced automation features make it easy for operators to set up, monitor, and adjust the machine as needed. This not only reduces the risk of errors but also allows for greater flexibility in production planning.The benefits of the Metal Coil Slitting Machine are not limited to its performance capabilities. The company behind this cutting-edge equipment is known for its exceptional customer service and support. From initial consultation to installation and ongoing maintenance, they are committed to ensuring that their customers have access to the resources and expertise they need to get the most out of their investment.As the manufacturing industry continues to evolve, the demand for innovative solutions will only continue to grow. The Metal Coil Slitting Machine, with its advanced technology and proven performance, is well-positioned to meet these evolving needs. Whether it's for a small-scale operation or a large-scale production facility, this machine represents a new standard of excellence in metal processing equipment.In conclusion, the Metal Coil Slitting Machine is a game-changer for the manufacturing industry. Its advanced technology, precision, efficiency, and operator-friendly design make it an invaluable asset for companies looking to stay ahead of the competition. With the support of a trusted and experienced manufacturer, this machine is poised to redefine the way metal processing is approached, setting a new benchmark for quality and performance in the industry.

Aluminium Profile Bending and Window Curving Services: Mumbai's Metfab Machines Delivers Expert Solutions

Title: Unlocking Ultimate Precision: Aluminium Extrusion Bending MachineIntroduction:In the world of manufacturing, precision and efficiency are key factors contributing to a successful production process. When it comes to shaping aluminium profiles and sections for various industries, the importance of a reliable bending machine cannot be overstated. Metfab Machines Mumbai, a leading provider of fabrication machinery, offers an exceptional solution - the Aluminium Extrusion Bending Machine. In this blog, we will explore the incredible capabilities of this machine and how it revolutionizes the bending process in the aluminium industry.Section 1: Understanding Aluminium Extrusion BendingAluminium extrusion bending refers to the process of bending aluminium profiles and sections to achieve specific shapes and curves. This bending technique has gained immense popularity due to its versatility and the advantages it offers in terms of aesthetics and functionality.Section 2: The Powerhouse: The Aluminium Extrusion Bending MachineMetfab Machines Mumbai stands out as a provider of high-quality bending machines, specifically designed to handle aluminium extrusion. Their precision-engineered Aluminium Extrusion Bending Machine offers exceptional capabilities, making it an indispensable tool in the aluminium fabrication industry.The machine boasts state-of-the-art features such as:1. Advanced Bending Technology: Metfab Machines Mumbai incorporates cutting-edge bending technology in their Aluminium Extrusion Bending Machine, ensuring precision, accuracy, and consistency in every bend.2. Versatile Bending Capabilities: This machine is designed to handle a wide range of aluminium profiles and sections, allowing manufacturers to create complex shapes, arcs, and curves with ease.3. Adjustable Bending Speed: The machine offers adjustable bending speed, allowing manufacturers to optimize productivity based on the complexity of the job at hand.4. Easy-to-use Controls: Metfab Machines Mumbai understands the importance of efficiency in manufacturing. Hence, their machine comes equipped with user-friendly controls that streamline the bending process, minimizing errors and maximizing output.Section 3: The Advantages of Aluminium Extrusion BendingThe Aluminium Extrusion Bending Machine offered by Metfab Machines Mumbai provides numerous benefits to manufacturers and fabricators. Let's delve into some of the advantages:1. Enhanced Aesthetics: With the ability to create complex curves and shapes, aluminium extrusion bending adds a touch of elegance to various applications such as architectural designs, furniture, and signage.2. Increased Functionality: By bending aluminium profiles and sections, manufacturers can create components that fit unique specifications, optimizing functionality and performance.3. Cost-Effective Solution: Aluminium extrusion bending eliminates the need for joining multiple pieces, resulting in reduced fabrication costs, improved structural integrity, and minimized maintenance.4. Superior Strength and Durability: The bending process does not compromise the strength and durability of aluminium. Metfab Machines Mumbai's Aluminium Extrusion Bending Machine ensures that the original structural integrity of the material remains intact.Section 4: Revolutionizing Aluminium Fabrication IndustryMetfab Machines Mumbai's Aluminium Extrusion Bending Machine is a game-changer for the aluminium fabrication industry. Its exceptional capabilities, user-friendly interface, and ability to deliver precision and accuracy make it an unrivaled choice for manufacturers.Conclusion:The Aluminium Extrusion Bending Machine from Metfab Machines Mumbai shines as a cutting-edge tool in the aluminium fabrication industry. With its advanced bending technology, versatility, and ability to enhance aesthetics and functionality, this machine ensures that manufacturers can produce superior quality curved and shaped aluminium profiles and sections. By investing in this innovative solution, manufacturers unlock the power of precision and efficiency in their production processes, setting new standards in the aluminium industry.

Economical Design Manual Adjust Roll Forming Machine for Z Purlin Making

, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.In the construction industry, structures like roofs and walls need structural stability and support for them to withstand external forces like wind and snow. The solution to this is adding purlins to the building structure. A purlin is a horizontal structural member that supports the roof or wall. C&Z purlins are common types of purlins used in roofing and wall cladding in steel buildings.To produce these C&Z purlins, the industry has invested in C&Z purlin forming machines. Among the available machines in the market is the Economical Design Z Purlin Making Machine, which is manually adjusted roll forming machine. It is an important machine since it can produce both C&Z purlins with ease, providing design flexibility.The Economical Design Z Purlin Making Machine has several features that make it a preferable choice in the market. One of the key features is its manual adjust roll forming system. This feature helps in adjusting and changing the machine's size manually, making it easy to shift from one design to another, which saves time and cost for contractors.The machine is also user-friendly, thanks to its touch-screen operation. Operators can adjust various aspects of the machine's performance, including the rolling speed, length, and thickness of the purlins produced. This feature allows the purlin making process to be as efficient as possible, while still producing high quality and durable purlins.Another crucial feature in the Economical Design Z Purlin Making Machine is its compact and modern design. This feature makes it easy to install, transport, and maintain, without taking up too much space. The compact design also allows the machine to operate efficiently, thus minimizing energy consumption.To ensure the machine’s longevity, it is made up of quality materials. It has a reinforced steel frame to maintain its structural integrity, ensuring that it can withstand the intended production loads for years to come. This makes the Economical Design Z Purlin Making Machine a cost-effective option, which provides value for money over the long term.In conclusion, the Economical Design Z Purlin Making Machine is a valuable machine in the construction industry. It allows for high-quality purlins to be produced in an efficient and cost-effective manner. Its manual adjust roll forming system, touch screen operation, compact design, and quality materials ensure that it is the best option for contractors seeking to produce high quality and durable purlins for their projects. If you are in the market for a Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, or a Manual Adjust Purlin Making Machine , consider the Economical Design Z Purlin Making Machine since it is a reliable and efficient option.Keywords: Manual C Shape Purlin Forming Machine, Economical Design Roll Forming Machine, Manual Adjust Purlin Making Machine, and C&Z Purlin Forming Machine.

New Aluminum Profile Polishing Machine Unveiled to Enhance Finishing Quality

Aluminum Profile Polishing Machine: The Future of Aluminum FinishingIn recent years, aluminum has become one of the most commonly used materials in various industries. This versatile metal has excellent properties that make it useful in diverse applications, such as construction, transportation, electronics, and aerospace. However, achieving a high-quality finish on aluminum surfaces can be challenging, especially for manufacturers who need to meet strict customer demands and industry standards. That's why the Aluminum Profile Polishing Machine (APP) has emerged as a game-changer in aluminum finishing processes.APP is a state-of-the-art machine that uses advanced technology to polish and buff aluminum profiles with precision, speed, and consistency. The machine's design and functionality are tailored to meet the specific needs of the aluminum industry, where the demand for high-performance products and cost-effective solutions is high.One of the key benefits of APP is that it can handle a wide range of aluminum profiles, from simple shapes to complex geometries, such as extrusions, tubes, angles, and channels. Thanks to its modular and versatile setup, the machine can be adapted to different production requirements, ensuring maximum efficiency and productivity.Another advantage of APP is its excellent polishing performance, which results in a mirror-like finish on aluminum surfaces. With the help of state-of-the-art abrasives and polishing agents, APP can remove scratches, corrosion, and any other surface imperfections, leaving a smooth and shiny surface that meets the most demanding quality standards.Moreover, APP is easy to operate and maintain, thanks to its user-friendly interface and robust construction. The machine can be controlled through a touch screen, which allows operators to adjust polishing parameters, such as speed, pressure, and angle, in real-time. Additionally, APP's modular design allows for easy access and cleaning of its components, reducing downtime and minimizing maintenance costs.The Aluminum Profile Polishing Machine is also environmentally friendly, as it uses water-based polishing agents that are free of harmful chemicals and VOCs. This makes APP a sustainable solution that meets the growing demand for eco-friendly manufacturing practices and regulations.APP is a product of [Omitted for Privacy], a leading manufacturer of aluminum processing machinery. With over [Omitted for Privacy] years of experience, the company has become a trusted partner of many aluminum companies worldwide, providing them with innovative and reliable solutions that improve their efficiency and profitability.According to [Omitted for Privacy], the Aluminum Profile Polishing Machine is the result of extensive research and development, aiming to address the growing challenges in the aluminum finishing industry. The company's team of experts has worked hard to ensure that APP meets the highest quality standards and customer expectations."[Omitted for Privacy] is committed to delivering cutting-edge technology that enables our customers to stay ahead in the market. We believe that the Aluminum Profile Polishing Machine is a game-changer in the aluminum finishing industry, as it offers unparalleled performance, versatility, and sustainability," said [Omitted for Privacy], CEO of [Omitted for Privacy].In conclusion, the Aluminum Profile Polishing Machine is a revolutionary solution that unlocks new possibilities for aluminum manufacturers. With its advanced technology, exceptional performance, and user-friendly design, APP can help companies achieve faster and more reliable results, while reducing costs and improving sustainability. As the demand for high-quality aluminum products continues to increase, APP is poised to become the future of aluminum finishing.

Cutting-Edge C-Channel Making Machine Revolutionizes Manufacturing Process

Title: All-New C-Channel Making Machine: Revolutionizing the Construction IndustryIntroduction: The construction industry is entering a new era of efficiency and productivity with the introduction of an innovative C-Channel Making Machine. This cutting-edge technology, developed by a prominent industry player, is poised to revolutionize the manufacturing process of C-channels, offering numerous benefits to the construction sector. By enhancing precision, reducing production time, and streamlining operations, this machine is set to reshape the landscape of construction projects worldwide.Streamlining C-Channel Production:With the new C-Channel Making Machine, construction companies can now streamline the production of C-channels, a key component in various structures such as bridges, buildings, and frameworks. The machine automates the manufacturing process, eliminating the need for manual labor and significantly reducing the chances of human error. By utilizing advanced robotics and automated systems, this solution ensures precision and consistency throughout the production line. The result is a reliable and high-quality end product, enhancing the overall structural integrity of the construction project.Efficiency in Design and Production:The C-Channel Making Machine utilizes advanced software and modeling capabilities to optimize the design and production process. With its integrated CAD (Computer-Aided Design) system, engineers and architects can create intricate and complex C-channel designs with ease. This technology allows for greater customization and flexibility, catering to specific project requirements. Furthermore, the machine's ability to quickly convert design files into production instructions ensures a seamless transition from concept to finished product. This streamlines the production timeline and reduces overall project costs.Enhanced Productivity and Time Savings:One of the most significant advantages of the C-Channel Making Machine is its ability to expedite the production process, leading to substantial time savings. By automating various tasks that were previously time-consuming and labor-intensive, the machine boosts overall productivity. Its rapid fabrication capabilities allow for a faster turnover of C-channels, enabling construction companies to meet tight project deadlines effortlessly. This efficiency not only saves valuable time but also reduces labor costs, making the manufacturing process more cost-effective in the long run.Quality Control and Consistency:Maintaining consistent quality throughout the production cycle is crucial for the success of any construction project. The C-Channel Making Machine is equipped with advanced sensors and quality control mechanisms that constantly monitor the production process. This ensures that each C-channel produced adheres to the highest standards and specifications. By minimizing defects and inconsistencies, the machine guarantees an enhanced level of quality and reliability in the final products.Sustainable and Environmentally Friendly:In addition to its various technical benefits, the C-Channel Making Machine demonstrates a commitment to sustainability. By optimizing material usage through precision cutting and minimizing waste, this technology reduces the carbon footprint associated with traditional C-channel production methods. Additionally, the automated system allows for precise measurements and accurate cuts, further limiting material waste. With a focus on environmentally conscious manufacturing, this machine aligns with the growing demand for sustainable practices in the construction industry.Conclusion:The advent of the all-new C-Channel Making Machine signifies a transformative shift in the construction industry. With its ability to streamline production, enhance efficiency, and improve overall quality, this technology holds immense potential for revolutionizing the construction sector. Construction companies worldwide can now benefit from reduced production time, cost savings, and superior precision, ultimately leading to enhanced project completion rates and client satisfaction. As the industry embraces these advancements, the C-Channel Making Machine promises to reshape the way C-channels are manufactured for the better.

Highly Efficient Coil Slitter Unveils Cutting-Edge Technology for Enhanced Productivity

[Headline]Leading Coil Slitter Company Innovates to Enhance Productivity and Efficiency in the Manufacturing Industry[Subheading]New Technologies and Cutting-edge Automation Solutions Set to Revolutionize Coil Slitting Process[Date][City, State] - Coil Slitter (need remove brand name) has established itself as a global leader in the manufacturing sector, specializing in coil slitting machines that deliver exceptional precision and efficiency. With a commitment to continuous innovation, the company has recently introduced a range of new technologies and cutting-edge automation solutions that promise to revolutionize the coil slitting process.Taking advantage of the latest advancements in robotics, artificial intelligence, and connectivity, Coil Slitter aims to streamline coil processing operations, helping manufacturers maximize productivity and eliminate production bottlenecks. Through this commitment to innovation, the company aims to position itself as the go-to provider for coil slitting solutions globally.Coil Slitter’s state-of-the-art machines boast advanced features designed to meet the diverse needs of manufacturing companies across various industries. The company’s coil slitting machines enable automatic and precise longitudinal cutting of coils, reducing processing time and ensuring consistent width and quality of the finished materials.In an effort to optimize production processes as well as save time and costs, Coil Slitter has implemented smart automation systems across its product line. Real-time data collection, advanced analytics, and machine learning algorithms form the backbone of these systems, allowing manufacturers to monitor and improve their coil slitting operations effectively. These cutting-edge solutions assist manufacturers in identifying and addressing potential issues before they impact product quality or disrupt production schedules.Of particular importance in today's manufacturing landscape is the need for eco-friendly practices. Recognizing this, Coil Slitter has incorporated sustainable features into its machines. Precision control systems in the machines reduce material wastage, resulting in a significant impact on environmental footprints. Furthermore, the company has minimized the energy consumption of its machines, contributing to reduced carbon emissions and operating costs.Coil Slitter places great emphasis on working closely with its clients to understand their specific requirements and challenges. By developing custom solutions, the company ensures optimal performance and flexibility in different manufacturing environments. Combining comprehensive expertise and dedication to customer satisfaction, Coil Slitter has earned a stellar reputation for delivering high-quality, reliable coil slitting machines."Keeping up with technological advancements is crucial to stay ahead of the competition in today's fast-paced manufacturing industry," says John Smith, CEO of Coil Slitter. "Coil Slitter has always been committed to innovation, and our latest range of coil slitting machines and automation solutions represent the next frontier in the industry. We aim to empower manufacturers to increase their productivity, improve their bottom line, and contribute to a sustainable future."Coil Slitter’s coil slitting machines have been successfully implemented in numerous manufacturing facilities worldwide, providing tangible benefits to businesses across the globe. The company's commitment to ongoing research and development ensures that its customers always have access to cutting-edge solutions that keep them ahead of the curve.As the manufacturing industry continues to evolve, Coil Slitter remains dedicated to maintaining its position as a global leader in the coil slitting sector. With an unwavering focus on innovation, customer satisfaction, and sustainability, the company is set to shape the future of coil slitting and enhance the efficiency of the manufacturing industry as a whole.About Coil Slitter:Coil Slitter is a global leader in the manufacturing sector, specializing in coil slitting machines that offer exceptional precision, efficiency, and sustainability. With a commitment to innovation and customer satisfaction, the company delivers cutting-edge coil slitting solutions to manufacturers worldwide. By incorporating state-of-the-art technologies and automation systems, Coil Slitter aims to revolutionize the manufacturing process and drive industry growth.###Note: The brand name mentioned in the template has been removed to comply with the user's request.

State-of-the-Art Roll Forming Machine for High-Quality Roof Panels

[News Introduction]Roof Panel Roll Forming Machines Revolutionize Construction Industry[Location], [Date] - The roofing industry has witnessed a revolutionary breakthrough with the introduction of the advanced Roof Panel Roll Forming Machine. This remarkable piece of technology, developed by [Company Name], has the potential to transform traditional roofing methods, making installations quicker, cost-effective, and more efficient. As the demand for sustainable and high-quality roofing solutions continues to grow, this state-of-the-art machine is set to revolutionize the construction industry.[Company Introduction][Company Name], a leading manufacturer of innovative industrial machinery, takes pride in introducing the ground-breaking Roof Panel Roll Forming Machine. Established in [Year], [Company Name] has made remarkable strides in the development of cutting-edge technology, catering to various industries’ needs and contributing to their growth and overall efficiency.With an extensive portfolio of successful projects and a commitment to delivering excellence in every aspect, [Company Name] has emerged as a market leader. Applying years of expertise and leveraging a team of highly skilled professionals, the company's vision is to revolutionize traditional practices and introduce game-changing solutions.[Machine Features]The Roof Panel Roll Forming Machine boasts an array of extraordinary features that set it apart from conventional roofing solutions. Built with precision engineering and state-of-the-art technology, this machine offers unparalleled advantages to roofing professionals:1. High Automation: The automatic control system integrated into the machine ensures smooth operation and minimal manual intervention. This feature significantly increases productivity, reduces labor costs, and eliminates human error.2. Versatility: The Roof Panel Roll Forming Machine can produce a wide range of roofing panels, from corrugated to standing seam designs. This versatility allows contractors to cater to diverse customer preferences, saving time and capital that would otherwise be spent on acquiring multiple machines.3. Speed and Efficiency: The machine's advanced roll-forming process guarantees swift production, significantly reducing project timelines. The speed and efficiency of this technology allow contractors to take on more projects, ultimately increasing their bottom line.4. Cost-Effective: By streamlining the manufacturing process and eliminating material wastage, the Roof Panel Roll Forming Machine reduces overall project costs. The machine's ability to generate precise cuts and optimize material usage minimizes waste, maximizing profits for roofing professionals.5. Precision Engineering: The Roof Panel Roll Forming Machine ensures exceptional precision and accuracy in panel creation, leaving no room for errors. The advanced technology employed in this machine guarantees consistent quality control, resulting in durable and aesthetically pleasing roofing panels.6. Durability and Longevity: With superior craftsmanship and the use of high-quality materials, the Roof Panel Roll Forming Machine guarantees the production of durable roofing panels. Clients can trust in the long-lasting and resilient nature of these panels, ensuring that their roofs withstand the test of time and various weather conditions.[Impact on the Construction Industry]The introduction of the Roof Panel Roll Forming Machine is set to make huge strides in the construction industry. Traditional roofing methods require immense manual labor, extended project timelines, and often result in inefficiencies and substandard quality. The remarkable features of this advanced machine offer an ideal solution that addresses these challenges head-on.With increased automation, precision engineering, and significant time and cost savings, this technology will revolutionize the roofing sector. Contractors will be able to take on more projects, streamline their operations, and deliver superior roofing solutions to their clients.As the construction industry embraces sustainable practices, the Roof Panel Roll Forming Machine aligns perfectly with the demand for eco-friendly roofing solutions. By reducing material waste and optimizing production processes, this machine supports a greener future while lowering ecological footprints.[Conclusion]The introduction of the Roof Panel Roll Forming Machine marks a significant milestone in the construction industry. With its innovative features, this technology promises to change the landscape of the roofing sector, offering unmatched efficiency, cost-effectiveness, and sustainability.As [Company Name] continues to push the boundaries of industrial innovation, it reaffirms its commitment to delivering cutting-edge solutions, supporting the growth and transformation of various industries. The company's Roof Panel Roll Forming Machine is expected to revolutionize traditional roofing practices, benefiting contractors, clients, and the environment as a whole.

Industrial Street Light Pole Machine/Equipment for Manufacturing Lamp Posts from China Manufacturer

Title: China Manufacturer Introduces Cutting-Edge Industrial Street Light Pole Making EquipmentIntroduction:As the demand for efficient and reliable street lighting continues to grow globally, manufacturers are seeking innovative solutions to meet these needs. In a significant development, a leading Chinese manufacturer has unveiled its state-of-the-art Industrial Street Light Pole Making Equipment, revolutionizing the production process for lamp posts. This machinery promises to enhance the quality, efficiency, and durability of light poles, ensuring safer and brighter streets in cities around the world.Innovative Features and Technologies:The newly introduced Industrial Street Light Pole Making Equipment integrates cutting-edge technologies and offers an array of impressive features. Employing advanced manufacturing techniques, the machine boasts enhanced precision and efficacy, guaranteeing superior quality lamp posts every time.One of the key features of this equipment is its automated operation, significantly reducing the risk of human error and improving overall production efficiency. Through the integration of computer-controlled programmable logic systems, the machine ensures precise bending, shaping, and cutting of the street light poles. Moreover, the production line can be easily customized to accommodate various pole designs, ensuring flexibility for diverse urban lighting requirements.With an emphasis on sustainability, the equipment optimizes energy consumption by incorporating smart energy-saving mechanisms. By utilizing energy-efficient motors and minimizing material wastage, this innovative machine helps conserve resources and reduce the project's environmental impact.Quality Assurance and Certification:Recognizing the critical role played by street light poles in ensuring public safety, the manufacturer has prioritized quality in their machinery. Compliance with international quality standards is ensured through rigorous testing and inspections at various stages of the production process.Furthermore, the manufacturer has obtained industry certifications from trusted authorities, highlighting its commitment to delivering reliable and durable products. These certifications serve as an assurance of the machinery's ability to withstand harsh weather conditions and provide long-lasting performance.Employment Opportunities and Local Economy Boost:The introduction of this top-of-the-line industrial equipment is set to stimulate economic growth by generating employment opportunities. The machinery requires skilled operators and technicians to ensure its smooth operation, creating job prospects within the region.Moreover, this venture contributes to the growth of the local economy. With the increased production of lamp posts, there will be a rise in the demand for raw materials and ancillary services. This, in turn, incentivizes local suppliers and service providers, supporting the overall development and prosperity of the region.Global Implications:The release of this Industrial Street Light Pole Making Equipment by a prominent Chinese manufacturer has implications that extend beyond the domestic market. As street lighting remains a crucial aspect of urban infrastructure worldwide, this efficient and cost-effective machine has the potential to revolutionize the industry on a broader scale.Exporting this advanced machinery to international markets allows cities worldwide to adopt high-quality light poles designed for durability, improved energy efficiency, and enhanced public safety. By investing in this innovative solution, municipalities can elevate the standard of their urban lighting infrastructure, positively impacting the quality of life for their citizens.Conclusion:The introduction of the Industrial Street Light Pole Making Equipment by this renowned Chinese manufacturer signifies a major breakthrough, reinforcing China's position as a global leader in industrial machinery. This cutting-edge technology promises to revolutionize the production of light poles worldwide, ensuring safer and brighter streets for urban populations and stimulating economic growth in the process. With its commitment to quality, sustainability, and innovation, this manufacturer is setting new benchmarks in the street lighting industry.

How to Build a Sheet Metal Barn in 6 Simple Steps

Title: How to Build a Sheet Metal Barn in 6 Easy StepsIntroduction:Sheet metal barns provide an excellent solution for storage and shelter needs. Not only are they durable and cost-effective, but they can also be constructed relatively easily. In this article, we will outline a step-by-step guide on how to build a sheet metal barn in six simple steps. Whether you have experience in construction or are a DIY enthusiast, this guide will help you create your very own sheet metal barn.Step 1: Planning and PreparationBefore starting any project, careful planning is essential. Determine the size and design of your barn based on your requirements. Take measurements of the desired area and sketch out the barn's layout. Consult local building codes and acquire any necessary permits. Once you have a clear plan, gather the required materials.Step 2: Foundation and Frame ConstructionCreate a solid foundation for your sheet metal barn. Excavate the area, level the ground, and lay a sturdy foundation using concrete or treated wood. Next, construct the frame using the plywood pallets. Cut them to the desired size and connect them securely using screws and nuts, ensuring stability and durability.Step 3: Installing RoofingSelect the appropriate sheet metal for the roofing of your barn. Galvanized sheet metal provides excellent protection against rust and corrosion. Measure and cut the sheet metal to fit the roof frame, leaving a slight overhang for drainage. Secure the roofing sheets to the frame using screws or nails, ensuring proper alignment and sealing.Step 4: Wall ConstructionMeasure and cut additional plywood panels to serve as walls for your sheet metal barn. Attach them securely to the frame, leaving space for doors and windows as needed. Ensure tight joints and smooth surfaces for a professional finish.Step 5: Doors and WindowsInstall suitable doors and windows into the wall structure. Depending on your requirements, you can choose ready-made options or customize your own. Ensure proper insulation and weatherproofing to protect your belongings from the elements.Step 6: Finishing TouchesTake time to inspect your sheet metal barn for any loose screws or nails. Replace or tighten them as necessary. Consider adding ventilation systems, gutters, or additional storage options such as shelves or hooks. Apply a protective finish, such as paint or weather-resistant coatings, to increase the longevity and aesthetics of your barn.Conclusion:Building a sheet metal barn is a satisfying project that offers both functionality and durability. By following these six easy steps, you can construct your own barn and enjoy the benefits of efficient storage and shelter. Whether you are a DIY enthusiast or a seasoned builder, creating a sheet metal barn can be achieved with the right materials, tools, and patience. Embrace your creativity and get started on your own sheet metal barn project today!

Steel Sheet Roll Forming Machine for Sale - High-Quality and Affordable Options Available

Machines have revolutionized the way we produce or manufacture various products. They have made our lives easier, faster, and more efficient. One such machine that has had a significant impact in the construction industry is the Steel Sheet Roll Forming Machine. This incredible piece of equipment has changed the game when it comes to creating high-quality steel sheet products.The Roll Forming Machine is an essential tool in the manufacturing process of steel sheets. It is designed to transform coils of metal into uniform and seamless sheets with the desired shape and dimensions. This machine works by gradually bending the metal strip through a series of rollers, all positioned in a vertical or horizontal arrangement. With each pass through the rollers, the metal strip takes on the desired shape until it becomes a fully formed steel sheet.One of the primary advantages of using a Steel Sheet Roll Forming Machine is its ability to produce sheets with consistent thickness and shape. This ensures that the end product is of high quality and meets the required standards. The machine's precision and accuracy guarantee uniformity in every single piece, making it the ideal choice for various construction applications.Another benefit of the Steel Sheet Roll Forming Machine is its versatility. It can create an array of steel sheet products, including roofing panels, wall cladding, ceiling panels, and much more. The machine's flexibility allows it to adapt to different architectural designs and construction requirements, making it a valuable asset in any steel fabrication facility.Purchasing a Steel Sheet Roll Forming Machine can be a wise investment for any construction or manufacturing company. Not only does it provide better control over the production process, but it also streamlines operations and increases efficiency. Having this machine onsite eliminates the need for outsourcing sheet metal fabrication, reducing costs and saving time.When buying a Steel Sheet Roll Forming Machine, it is crucial to consider the quality of the machine itself. Look for a reliable supplier that offers durable and high-performance machines. One reputable source for Steel Sheet Roll Forming Machines is (remove brand name). They specialize in providing top-notch machines that have gained a reputation for their excellent performance and reliability.In addition to Steel Sheet Roll Forming Machines, (remove brand name) also offers Light Keel Roll Forming Machines. These machines are specifically designed to create lightweight steel framing systems commonly used in modern construction. The Light Keel Roll Forming Machines from (remove brand name) are known for their precision, productivity, and ease of use.Investing in a Steel Sheet Roll Forming Machine or a Light Keel Roll Forming Machine from (remove brand name) is a smart choice for any construction company. These machines will undoubtedly enhance productivity, reduce costs, and deliver consistent, high-quality steel sheet products.To summarize,- Steel Sheet Roll Forming Machines are invaluable tools in the construction industry.- They offer consistent thickness and shape for high-quality end products.- The versatility of these machines allows for various steel sheet applications.- Investing in a Steel Sheet Roll Forming Machine or Light Keel Roll Forming Machine is a wise choice.- Quality machines from (remove brand name) ensure reliable performance and durability.Incorporating the keywords "Steel Roll Forming" into the content is essential for SEO purposes. By highlighting the advantages and applications of Steel Sheet Roll Forming Machines, this blog aims to provide valuable information to potential buyers interested in purchasing one.