Top Portable Standing Seam Roll Former for Seamless Roofing

By:Admin

In the world of metal roofing, there has been a revolutionary advancement that is changing the way roofs are installed on construction sites. With the introduction of the Portable Standing Seam Roll Former, the process of metal roofing installation has been streamlined and made significantly more efficient.

This innovative machine, designed and manufactured by a leading metal roofing company, is a game changer in the industry. Thanks to its portability and easy setup, the Portable Standing Seam Roll Former allows for on-site fabrication of standing seam metal roofing panels. This eliminates the need for pre-fabricated panels to be transported to the site, cutting down on logistical challenges and costs associated with traditional metal roofing installation.

The company behind this groundbreaking technology has been a pioneer in the metal roofing industry for over two decades. They have a strong reputation for their commitment to quality, innovation, and customer satisfaction. This portable roll former is the latest addition to their impressive line of products and solutions, and it has quickly become a game changer in the industry.

One of the most significant advantages of the Portable Standing Seam Roll Former is its portability. Unlike traditional roll formers, which are large and stationary, this portable machine can be transported to the construction site with ease. This means that metal roofing panels can be fabricated and installed on site, eliminating the need for costly and time-consuming transportation of pre-fabricated panels.

Additionally, the Portable Standing Seam Roll Former is incredibly user-friendly and easy to set up. It can be operated by a small team of workers, reducing the need for specialized labor and cutting down on installation time. This not only improves efficiency but also helps to drive down costs for contractors and construction companies.

Furthermore, the on-site fabrication of standing seam metal roofing panels allows for greater customization and precision. The Portable Standing Seam Roll Former can accommodate different panel profiles, widths, and lengths, providing flexibility to meet the specific requirements of each project. This level of customization ensures a perfect fit and finish for every roof, resulting in a high-quality and durable roofing system.

The company's commitment to innovation and excellence is evident in the design and performance of the Portable Standing Seam Roll Former. Using state-of-the-art technology and engineering, they have created a machine that is not only efficient but also produces high-quality standing seam metal roofing panels. This ensures that the final product meets the highest standards of durability and performance, providing long-lasting protection for buildings and structures.

The impact of the Portable Standing Seam Roll Former is far-reaching, as it has the potential to transform the metal roofing industry. By making on-site fabrication more efficient and cost-effective, this innovative machine is empowering contractors and construction companies to take on metal roofing projects with confidence. It is also helping to drive the adoption of metal roofing as a sustainable and long-lasting solution for a wide range of buildings and structures.

In conclusion, the introduction of the Portable Standing Seam Roll Former is a game changer in the metal roofing industry. With its portability, ease of use, and ability to provide on-site fabrication of standing seam metal roofing panels, this innovative machine is revolutionizing the way roofs are installed. The company behind this groundbreaking technology continues to lead the industry with their commitment to quality, innovation, and customer satisfaction. Their Portable Standing Seam Roll Former is a testament to their dedication to providing cutting-edge solutions that drive efficiency, performance, and sustainability in the construction industry.

Company News & Blog

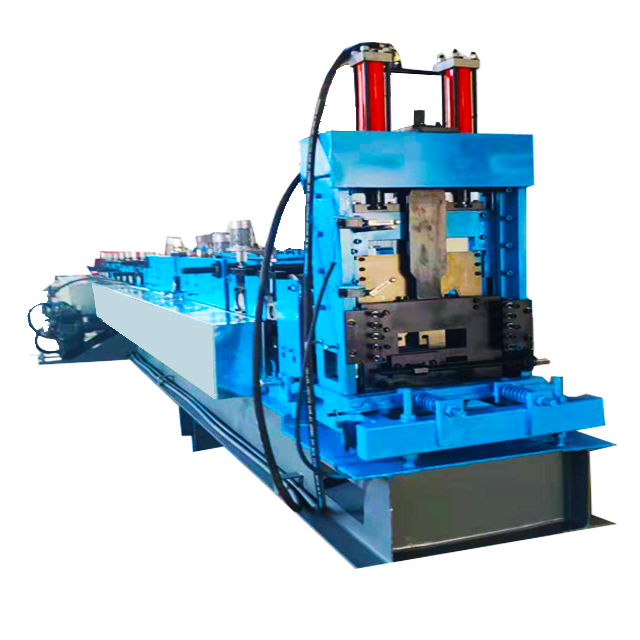

Fully Automatic C Purlin Roll Forming Machine: A Complete Guide

Fully Automatic C Purlin Roll Forming Machine Revolutionizing the Steel Structure IndustryThe steel structure industry has been revolutionized by the introduction of the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field. This innovative machine has significantly enhanced the efficiency and productivity of producing C purlins, which are essential components in the construction of steel buildings.With the increase in demand for steel structures due to their durability, cost-effectiveness, and flexibility, the need for advanced manufacturing equipment has become more critical. The Fully Automatic C Purlin Roll Forming Machine meets this demand by automating the production process, reducing manual labor, and increasing output.The machine's advanced technology allows for precise and accurate forming of C purlins, ensuring consistent quality and dimensional accuracy. This level of precision is essential for the seamless assembly and construction of steel buildings, where even the slightest deviation in the dimensions of components can result in installation challenges and structural issues.The Fully Automatic C Purlin Roll Forming Machine is designed to handle a wide range of materials, including galvanized steel, stainless steel, and aluminum, making it versatile for various construction requirements. This flexibility has made it an ideal choice for manufacturers, contractors, and construction companies looking to streamline their production processes and deliver high-quality steel structures to their clients.In addition to its advanced technology, the machine's fully automated operation has significantly reduced production time, allowing for faster turnaround times and increased production capacity. This has had a direct impact on the overall efficiency and profitability of steel structure manufacturing companies, enabling them to meet deadlines and fulfill orders more effectively.Furthermore, the machine's automated operation has also improved workplace safety by reducing the need for manual handling of heavy materials and minimizing the risk of work-related injuries. This has not only created a safer work environment for employees but has also contributed to the overall productivity of production facilities.The company behind the Fully Automatic C Purlin Roll Forming Machine has a long-standing reputation for delivering high-quality and reliable manufacturing equipment to the steel structure industry. With a team of experienced engineers and technicians, the company has been at the forefront of innovation, continuously developing and refining its products to meet the evolving needs of the industry.The company's commitment to research and development has resulted in the creation of cutting-edge technologies that have set new standards for efficiency, reliability, and performance in the manufacturing of steel components. The Fully Automatic C Purlin Roll Forming Machine is a testament to this dedication, as it represents the pinnacle of modern engineering and design in the steel structure industry.In addition to its technological expertise, the company also takes pride in its commitment to customer satisfaction, providing comprehensive support and service to ensure the seamless integration of its equipment into production facilities. This customer-centric approach has earned the company a loyal clientele and a reputation for being a trusted partner in the success of steel structure manufacturing businesses.Looking ahead, the Fully Automatic C Purlin Roll Forming Machine is poised to continue shaping the future of the steel structure industry, driving greater efficiency, precision, and profitability for manufacturers and construction companies. As the demand for steel structures continues to grow, this innovative machine will play a crucial role in meeting the industry's evolving needs and delivering exceptional results to clients around the world.In conclusion, the Fully Automatic C Purlin Roll Forming Machine, manufactured by a leading company in the field, has set new benchmarks for efficiency and productivity in the manufacturing of steel structures. With its advanced technology, automated operation, and versatile capabilities, this innovative machine has become an indispensable asset for the industry, driving greater precision, safety, and profitability for businesses. As the steel structure industry continues to evolve, the Fully Automatic C Purlin Roll Forming Machine stands ready to lead the way towards a future of excellence and innovation.

Advanced High-Speed Cut-To-Length Machines Revolutionize Industrial Operations

Title: Innovative High-Speed Cut-to-Length Machine Revolutionizes Industrial AutomationIntroduction:In today's ever-evolving manufacturing landscape, efficiency and precision are of paramount importance. As companies strive to optimize their production processes, a groundbreaking solution has emerged – the High-Speed Cut-to-Length Machine (CCLM) – a technological marvel that is set to revolutionize the industrial automation sector. Developed by an industry-leading manufacturer, this state-of-the-art machine combines cutting-edge technologies with a focus on speed, accuracy, and versatility. By improving productivity and ensuring higher quality outputs, the High-Speed CCLM promises to bring about a new era in manufacturing.[Paragraph 1: Background and Importance of Industrial Automation]Automation has long been a key imperative in the manufacturing sector, as it offers numerous benefits such as improved productivity, reduced labor costs, and enhanced product quality. However, until now, the cut-to-length process has remained a bottleneck for many industries. Traditional machinery often falls short in terms of accuracy, speed, and flexibility. The introduction of the High-Speed CCLM aims to address these limitations, enhancing efficiency while maintaining a high level of precision.[Paragraph 2: Overview of the High-Speed Cut-to-Length Machine]Developed by a leading manufacturer with a rich history of innovation, the High-Speed CCLM is a game-changer in the field of industrial automation. Boasting a combination of advanced technologies, meticulous engineering, and comprehensive user-centric design, this machine is capable of processing various materials at an unprecedented pace and accuracy. By seamlessly integrating automation features, such as robotic arms and powerful AI algorithms, the High-Speed CCLM is capable of precisely cutting and shaping an array of materials including metals, plastics, and composites.[Paragraph 3: Key Features and Advantages]The High-Speed CCLM differentiates itself from conventional machinery through several standout features that elevate it to a league of its own. First and foremost, this machine allows for rapid changeovers, enabling manufacturers to seamlessly transition between different types and sizes of materials. Furthermore, its high-speed operation significantly reduces manufacturing cycle times, leading to increased productivity and throughput. The use of advanced laser-guided technology ensures exceptional accuracy, while the incorporation of AI algorithms enables predictive maintenance, reducing downtime and maintenance costs.[Paragraph 4: Impact on Manufacturing Industry]The advent of the High-Speed CCLM is set to revolutionize the manufacturing industry as a whole. By streamlining the cut-to-length process, this machine eliminates the need for multiple manual interventions, thereby minimizing the risk of errors and accidents. Additionally, its high-speed capabilities enable manufacturers to meet ever-growing customer demands and tight production schedules efficiently. The automation features of the High-Speed CCLM also allow for simpler and more cost-effective scaling of operations, facilitating the growth of small-scale enterprises.[Paragraph 5: Case Studies and Customer Testimonials]Numerous businesses across various industries have already integrated the High-Speed CCLM into their manufacturing processes, yielding remarkable results. Companies that have implemented this innovative machine have reported significant improvements in productivity, waste reduction, and overall quality control. Customer testimonials highlight how the High-Speed CCLM has transformed their operations, saving them time and resources, while simultaneously enhancing their competitiveness in the market.[Paragraph 6: Conclusion]In conclusion, the introduction of the High-Speed Cut-to-Length Machine represents a significant milestone in the automation revolution within the manufacturing industry. With its advanced features, exceptional speed, and unmatched precision, this innovative machine is poised to redefine the way materials are cut and shaped, driving efficiency, and enhancing competitiveness for businesses across the globe. As industrial automation continues to evolve, the High-Speed CCLM sets a new benchmark for excellence, consolidating its position as a game-changer in the field.

High-quality Double Layers Color Steel Roll Forming Machine for Sale - Latest Technology

Double Layers Color Steel Roll Forming Machine Revolutionizes the Manufacturing IndustryAs technology continues to advance, the manufacturing industry is constantly on the lookout for innovative and efficient solutions to improve productivity and quality. Keeping this in mind, {Company Name}, a leading manufacturer in the industry, has introduced the Double Layers Color Steel Roll Forming Machine, a cutting-edge solution that is set to revolutionize the way color steel is produced.The Double Layers Color Steel Roll Forming Machine is designed to streamline the production process while ensuring top-notch quality and accuracy. It is a versatile machine that can accommodate a wide range of color steel materials, making it a valuable addition to any manufacturing setup. With the ability to form two different profiles in one machine, it offers flexibility and efficiency that is unparalleled in the industry.The machine is equipped with advanced technology that allows for precise and consistent forming of color steel, ensuring that each product meets the highest standards. It also comes with a user-friendly interface, making it easy for operators to control and monitor the entire process. This not only reduces the risk of errors but also increases overall productivity.One of the key features of the Double Layers Color Steel Roll Forming Machine is its ability to produce color steel with a smooth, flawless finish. This is crucial in the manufacturing of various products, such as roofing and cladding materials, where the aesthetics of the final product are of utmost importance. With this machine, manufacturers can achieve a consistent and high-quality finish, thereby enhancing the value of their products.Furthermore, the machine is designed with efficiency in mind, ensuring that the production process is streamlined and cost-effective. By reducing manual labor and optimizing material usage, manufacturers can significantly lower their production costs while increasing output. This not only improves their bottom line but also gives them a competitive edge in the market.{Company Name} has a long-standing reputation for delivering top-of-the-line manufacturing solutions, and the introduction of the Double Layers Color Steel Roll Forming Machine further solidifies its position as a leader in the industry. The company is committed to providing innovative and reliable equipment that meets the evolving needs of manufacturers, and this new machine is a testament to that commitment.In addition to the Double Layers Color Steel Roll Forming Machine, {Company Name} offers a comprehensive range of manufacturing equipment and solutions, making it a one-stop destination for all manufacturing needs. Whether it's roll forming, cutting, or packaging equipment, the company has the expertise and resources to cater to the diverse requirements of its clients.With a strong focus on research and development, {Company Name} is continuously pushing the boundaries of innovation in the manufacturing industry. The company invests heavily in developing cutting-edge technology and refining its existing products to ensure that it stays ahead of the curve. This commitment to excellence has earned {Company Name} a reputation for delivering quality and reliability, making it a trusted partner for manufacturers around the world.The introduction of the Double Layers Color Steel Roll Forming Machine is a significant milestone for {Company Name}, and it is set to make a lasting impact on the industry. With its advanced features and capabilities, the machine is poised to set a new standard in color steel production, offering manufacturers a competitive advantage that is unmatched.In conclusion, the Double Layers Color Steel Roll Forming Machine is a game-changer for the manufacturing industry, and {Company Name} is at the forefront of this innovation. With its commitment to excellence and track record of delivering top-notch solutions, the company continues to shape the future of manufacturing, driving efficiency, quality, and productivity to new heights. Whether it's the Double Layers Color Steel Roll Forming Machine or any other product in its portfolio, {Company Name} remains a beacon of innovation and reliability in the industry.

Efficient Roofing Manufacturing Machine: Boosting Productivity in the Industry

[Company Name] Revolutionizes Roofing Industry with Innovative Roofing Making Machine [City, Date] - [Company Name], a leading provider of advanced manufacturing solutions, has launched an innovative Roofing Making Machine that is set to revolutionize the roofing industry. The state-of-the-art machine, developed by a team of expert engineers and designers, promises to transform traditional roofing manufacturing processes and usher in a new era of efficiency and productivity.The Roofing Making Machine is a result of [Company Name]'s commitment to innovation and continuous improvement. The company's goal was to develop a solution that would address the challenges faced by the roofing industry in terms of high production costs, labor-intensive processes, and quality control. After years of research and development, the team at [Company Name] has successfully created a machine that surpasses expectations.One of the key features of this groundbreaking machine is its versatility. It is capable of producing various types of roofing materials, including metal sheets, shingles, tiles, and more. This means that roofing manufacturers no longer need to invest in multiple machines for different products, saving them both time and money. The Roofing Making Machine's adjustable settings allow for precise control over the production process, ensuring consistent and high-quality output every time.The machine's advanced automation capabilities have also caught the attention of industry experts. Equipped with cutting-edge technology, it significantly reduces the need for manual labor, thus minimizing the risk of human error and improving overall safety conditions. With the Roofing Making Machine, roofing manufacturers can expect increased production rates and enhanced productivity, ultimately resulting in a competitive edge in the market.In addition to its automation features, the Roofing Making Machine is designed with sustainability in mind. It utilizes energy-efficient components and incorporates eco-friendly practices throughout the manufacturing process. By reducing energy consumption and waste generation, the machine aligns with the global trend towards sustainable development and environmental conservation.The ease of use and user-friendly interface of the Roofing Making Machine have garnered positive feedback from early adopters. The intuitive controls and comprehensive training provided by [Company Name] ensure that roofing manufacturers can quickly adapt to the new technology without disruptions to their existing operations. The machine's ability to seamlessly integrate into existing manufacturing processes has been praised as a testament to [Company Name]'s customer-centric approach."We are thrilled to introduce the Roofing Making Machine to the market," said [Company Name]'s CEO. "It is our commitment to provide cutting-edge solutions that empower our customers and transform their businesses. The positive feedback we have received so far encourages us to continue pushing boundaries and innovating within the industry."The Roofing Making Machine is now available to roofing manufacturers worldwide, with [Company Name]'s extensive global network ensuring prompt delivery, installation, and after-sales support. As the demand for efficient and sustainable roofing solutions continues to grow, this revolutionary machine is poised to become a game-changer in the industry.About [Company Name]:[Company Name] is a globally recognized leader in advanced manufacturing solutions. With a focus on innovation and customer satisfaction, the company's diverse portfolio includes a wide range of machines and equipment for various industries. [Company Name]'s commitment to excellence and continuous improvement has earned them a reputation for delivering reliable, high-quality solutions that shape the future of manufacturing.For media inquiries, please contact:[Company Name][Contact Name][Email Address][Phone Number]

High-precision Slitting Line for Efficient Metal Processing

Cr Slitting Line, a cutting-edge technology used in the manufacturing industry, has recently been installed at the premises of [Company Name]. This new addition to the company's production facilities is expected to enhance the efficiency and precision of the cutting process for various materials, including steel, aluminum, and other metal alloys. The Cr Slitting Line is specifically designed to handle coils of varying widths and thicknesses, allowing for greater flexibility in the manufacturing process. It is equipped with state-of-the-art automation and control systems, ensuring consistent and accurate cutting results. The line also boasts high-speed capabilities, enabling fast and efficient processing of materials.With the installation of the Cr Slitting Line, [Company Name] aims to further improve its production capabilities and meet the growing demand for high-quality cut-to-length products. The company has a strong reputation for delivering precision-engineered metal components to a wide range of industries, including automotive, construction, and manufacturing. The addition of this advanced cutting technology underscores [Company Name]'s commitment to staying at the forefront of innovation in the industry.The Cr Slitting Line is set to revolutionize the cutting process at [Company Name] by enabling faster turnaround times, increased productivity, and improved material utilization. This cutting-edge technology will allow the company to offer a broader range of customized cutting solutions to its diverse customer base, catering to their specific requirements with unparalleled precision and quality.In addition to the technical capabilities of the Cr Slitting Line, [Company Name] is also committed to ensuring the highest standards of safety and environmental responsibility in its operations. The company has implemented rigorous safety protocols and measures to safeguard the well-being of its employees and minimize the environmental impact of its manufacturing processes.The installation of the Cr Slitting Line is a strategic investment for [Company Name] as it positions the company for future growth and expansion in the market. By incorporating this advanced cutting technology into its production facilities, the company is poised to enhance its competitive edge and solidify its position as a leading provider of cut-to-length solutions.The news of the installation of the Cr Slitting Line at [Company Name] has been met with excitement and anticipation within the industry. Customers, suppliers, and industry professionals alike have expressed their confidence in the company's ability to leverage this new technology to deliver even greater value and quality to its stakeholders.In summary, the installation of the Cr Slitting Line at [Company Name] represents a significant milestone in the company's ongoing commitment to innovation and excellence in manufacturing. This cutting-edge technology is set to redefine the company's cutting capabilities and propel it to new heights of success in the industry. With its unparalleled precision, speed, and efficiency, the Cr Slitting Line is poised to transform the way [Company Name] delivers cutting solutions to its customers, setting new standards for quality and performance in the manufacturing sector.

High-Quality Steel Sheet Making Machine for Efficient Production

The Steel Sheet Making Machine is a revolutionary piece of equipment that has the ability to transform raw materials into high-quality steel sheets with precision and efficiency. With its advanced technology and innovative design, the machine is set to revolutionize the steel manufacturing industry.The machine, developed by the leading steel manufacturing company, is the result of years of research and development. It incorporates the latest advancements in steel production technology, enabling it to produce steel sheets of superior quality at a faster rate than traditional methods.One of the key features of the Steel Sheet Making Machine is its automation capabilities. The machine is equipped with advanced robotics and control systems that allow it to operate seamlessly and with minimal human intervention. This not only improves production efficiency but also ensures consistent quality in every sheet produced.Furthermore, the machine is designed to be highly customizable, allowing for a wide range of steel sheet specifications to be produced. This versatility makes it an ideal solution for a variety of applications, from construction and automotive manufacturing to consumer goods production.In addition to its technological advancements, the machine also boasts enhanced safety features. With built-in sensors and safety mechanisms, the machine can detect and respond to potential hazards, ensuring a safe working environment for the operators.The company behind the Steel Sheet Making Machine has a long-standing reputation for innovation and excellence in the steel manufacturing industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in steel production, leading to the development of the highly advanced machine.In addition to its technical expertise, the company also places a strong emphasis on sustainability and environmental responsibility. The Steel Sheet Making Machine is designed to minimize waste and energy consumption, making it a more eco-friendly option compared to traditional steel manufacturing methods.Moreover, the company is committed to providing comprehensive support and maintenance services for the machine, ensuring that it continues to operate at its full potential throughout its lifespan.The introduction of the Steel Sheet Making Machine marks a significant advancement in the steel manufacturing industry. With its cutting-edge technology, high efficiency, and commitment to sustainability, the machine is set to redefine the way steel sheets are produced.As the demand for steel continues to grow across various industries, the Steel Sheet Making Machine offers a solution that is not only capable of meeting this demand but also of doing so in a way that is more efficient, reliable, and sustainable.The company is confident that the machine will have a significant impact on the steel manufacturing industry, providing manufacturers with a competitive edge in the market. With its advanced capabilities and commitment to excellence, the Steel Sheet Making Machine is poised to become a game-changer in the industry, setting new standards for quality and efficiency in steel production.In conclusion, the Steel Sheet Making Machine represents a major step forward in the steel manufacturing industry. With its advanced technology, customizable capabilities, and commitment to sustainability, the machine is poised to revolutionize the way steel sheets are produced, setting new benchmarks for quality, efficiency, and environmental responsibility. The company's dedication to innovation and excellence has culminated in the development of a truly groundbreaking machine that is set to shape the future of steel manufacturing.

High-quality Metal Roof Panel Making Machine for Efficient Roofing Production

Metal Roof Panel Making Machine Revolutionizing the Construction IndustryIn a world where efficiency and productivity are key factors in maintaining a competitive edge, the construction industry is constantly seeking innovative solutions to streamline operations. One such groundbreaking solution is the Metal Roof Panel Making Machine, which has been developed by a leading industry player, known for its expertise in manufacturing high-quality machinery for the construction sector.The Metal Roof Panel Making Machine is designed to revolutionize the process of manufacturing metal roof panels, which are an essential component in modern building construction. These panels are not only durable and low-maintenance but also provide a sleek and contemporary appearance, making them a popular choice for commercial and residential buildings alike.This state-of-the-art machine is equipped with advanced technology and automation, allowing for the seamless production of metal roof panels with precision and speed. It is capable of handling various types of metal materials, including steel, aluminum, and copper, and can produce panels of different shapes, sizes, and designs to cater to diverse project requirements.One of the key features that set this Metal Roof Panel Making Machine apart from traditional manufacturing methods is its ability to significantly reduce production time and labor costs. The machine's automated processes minimize the need for manual intervention, thereby optimizing efficiency and maximizing output. This not only benefits manufacturers by improving their bottom line but also translates to faster turnaround times for construction projects, ultimately benefiting the end-users.Furthermore, the Metal Roof Panel Making Machine boasts a user-friendly interface and intuitive controls, making it accessible to operators with varying levels of expertise. Its robust construction and reliable performance ensure consistent quality and durability of the produced panels, meeting the stringent standards of the construction industry.The company behind this groundbreaking innovation has a long-standing reputation for excellence in the field of construction machinery. With a focus on research and development, they have continuously strived to introduce cutting-edge solutions that address the evolving needs of the industry. Their commitment to quality, coupled with a customer-centric approach, has made them a trusted partner for construction companies worldwide.In addition to producing the Metal Roof Panel Making Machine, the company offers comprehensive support services, including installation, training, maintenance, and technical assistance. This full-service approach ensures that customers can harness the full potential of the machine, maximizing its performance and longevity.As the demand for metal roof panels continues to rise in the construction sector, the Metal Roof Panel Making Machine is poised to play a pivotal role in meeting this demand and setting new benchmarks for efficiency and excellence. Its impact is not limited to large-scale manufacturers but extends to contractors, builders, and developers who rely on high-quality metal roof panels to deliver exceptional results in their projects.In conclusion, the Metal Roof Panel Making Machine represents a game-changing innovation that is reshaping the landscape of the construction industry. With its advanced technology, automation, and superior performance, it is poised to elevate production standards and set a new paradigm for metal roof panel manufacturing. As the industry embraces this revolutionary solution, it is evident that the future of construction is being shaped by forward-thinking companies and their commitment to driving progress through innovation.

Clear and Transparent Corrugated Plastic Roofing Sheets for Your Home or Greenhouse

{Name Removed} Introduces New, High-Performance Horizontal Corrugated Roofing Material{Name Removed}, a leading manufacturer of roofing materials, has launched a new product that is set to revolutionize the industry - the Horizontal Corrugated Roofing Material. This high-performance roofing material is designed to provide unmatched durability, weather resistance, and ease of installation, making it perfect for a wide range of roofing applications.One of the standout features of the Horizontal Corrugated Roofing Material is its unique design. Unlike traditional corrugated roofing materials that are installed vertically, this product is installed horizontally. This design allows for superior water shedding, making it ideal for areas with heavy rainfall or snow.The Horizontal Corrugated Roofing Material is made from high-quality PVC and boasts exceptional strength and durability. It also has excellent UV resistance properties, making it ideal for use in areas with high sunlight exposure. The material is also resistant to corrosion and chemicals, ensuring it will retain its quality and appearance for many years.Another benefit of this product is its ease of installation. The Horizontal Corrugated Roofing Material is lightweight, making it easy to handle and transport. It can also be easily cut to size on-site using a common circular saw, reducing installation time and costs. Additionally, the product requires minimal maintenance, which means less time and money spent on repairs and upkeep.This new product from {Name Removed} has also been designed with environmental sustainability in mind. The material is 100% recyclable and free from harmful chemicals, making it an eco-friendly choice for homeowners and businesses.The Horizontal Corrugated Roofing Material comes in a range of attractive colours and finishes, making it a versatile and stylish roofing solution. It is also cost-effective, providing customers with a high-quality solution that won't break the bank.Commenting on the launch of the new product, a spokesperson for {Name Removed} said, "We are thrilled to introduce the Horizontal Corrugated Roofing Material to the market. This product is the result of our commitment to providing our customers with the best possible roofing solutions. We believe that this product is perfect for anyone looking for a durable, weather-resistant, and easy-to-install roofing option that offers exceptional value for money."In conclusion, if you are looking for a high-quality, durable, and eco-friendly roofing option, you should look no further than the Horizontal Corrugated Roofing Material from {Name Removed}. With its unique design, exceptional strength and durability, and ease of installation, this product is sure to be a game-changer in the roofing industry.

China's Leading Manufacturer Offers Comprehensive Roll Forming Solutions for Various Applications

Roofing Sheet Forming Machine: The Ultimate Solution for Precise and Efficient RoofingWhen it comes to roofing materials, choosing the right one is crucial to ensure the durability and aesthetics of a building. Among the various options available, roofing sheets have become increasingly popular due to their versatility and cost-effectiveness. However, to efficiently produce roofing sheets that meet specific requirements, a reliable and precise manufacturing process is essential. That's where a Roofing Sheet Forming Machine comes into play.A roofing sheet forming machine is an advanced piece of equipment designed specifically for the production of roofing sheets. It is widely used across various industries, including construction, architecture, and manufacturing. The machine utilizes the process of roll forming, which is known for its accuracy and efficiency in creating uniform and high-quality products.The roll forming process involves passing a sheet of metal through a series of rollers, gradually shaping it into the desired profile. With the use of custom-made molds, the machine can produce different types of roofing sheets, such as corrugated, trapezoidal, and standing seam profiles. This flexibility allows manufacturers to cater to a wide range of customer demands and project specifications.One of the significant advantages of using a Roofing Sheet Forming Machine is its ability to ensure precision and consistency throughout the production process. Each roller in the machine is uniquely designed to shape the metal sheet with precise measurements and dimensions. This results in roofing sheets that fit perfectly and are aesthetically pleasing.Additionally, the machine's high-speed operation enables manufacturers to produce a large volume of roofing sheets quickly. This not only saves time but also enhances productivity, making it an ideal choice for mass production. Furthermore, the machine's automated control system eliminates the need for manual labor, reducing the chances of errors and ensuring a safer working environment.Quality is of utmost importance when it comes to roofing materials, and a Roofing Sheet Forming Machine excels in delivering consistent and durable products. By using high-quality materials and advanced manufacturing techniques, these machines guarantee the production of roofing sheets that are resistant to corrosion, weathering, and wear. This durability ensures that the roofs constructed using these sheets can withstand harsh environmental conditions and provide long-lasting protection.In addition to its primary function of manufacturing roofing sheets, a Roofing Sheet Forming Machine offers several other benefits. It provides versatility by offering customizability options, allowing manufacturers to produce roofing profiles of different lengths, widths, and thicknesses. This ensures that they can cater to diverse customer requirements and project specifications.Moreover, the machine's operation is accompanied by minimal noise and vibration, thanks to its advanced engineering and quality construction. This reduces disturbances in the workplace and contributes to a peaceful working environment for employees. Additionally, the machine requires minimal maintenance, leading to lower operational costs and improved overall efficiency.As the demand for roofing sheets continues to rise, it is essential to choose a reliable and experienced manufacturer when investing in a Roofing Sheet Forming Machine. A reputable manufacturer will not only provide top-quality machines but also offer comprehensive support and service throughout the purchase process. They will assist in the selection of the right machine, provide installation and training, and offer after-sales support to ensure smooth and efficient operations.In conclusion, a Roofing Sheet Forming Machine is the ultimate solution for producing precise, durable, and cost-effective roofing sheets. Its ability to deliver consistent quality, high-speed production, and customizability makes it an indispensable piece of equipment in the roofing industry. So, whether you are a contractor, builder, or manufacturer, investing in a Roofing Sheet Forming Machine is a wise choice to elevate your roofing business to new heights.